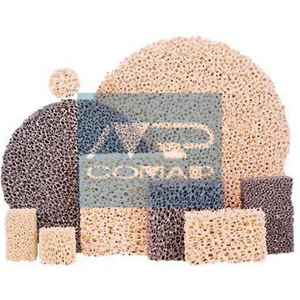

Ceramic filters for foundries

Ceramic filters are used in many industries but are particularly important in the foundry industry. Foundries require high temperatures to melt metals, and impurities in the metal can cause problems during the casting process. By using a ceramic filter, foundries can remove impurities from the metal before it is cast, resulting in a higher quality final product. In addition, ceramic filters help extend the life of molds and casting equipment by preventing damage from impurities. Therefore, ceramic filters have an essential function in the foundry industry, and their importance is expected to increase in the future.

Ceramic filters are an important part of the metal casting process in foundries. They are used to help smooth the flow of molten metal and result in a more consistent flow of molten metal. The ceramic filter is placed in the mold cavity, and molten metal is fed into the mold through the filter. The filter allows the metal to flow into the mold, filling any gaps and creating a smooth surface. In addition, ceramic filters help eliminate cavities and pores in the casting, leading to a stronger and more durable final product. The result is a better-quality molding with minimal imperfections. Ceramic filters also help to reduce the quantity of smoke and fumes produced during the casting process. This makes the working environment safer for the foundry workers.

There are two types of filters, foam filters and regulators. Filters can be doped with nodulizers

For over 40 years we have specialized in the import and export of consumables for the steel industry. We have established close relationships with our customers worldwide. If you are looking for ceramic filters, please feel free to contact us, we stay at your disposal.